ETC epoxy adhesives

ETC epoxy adhesives

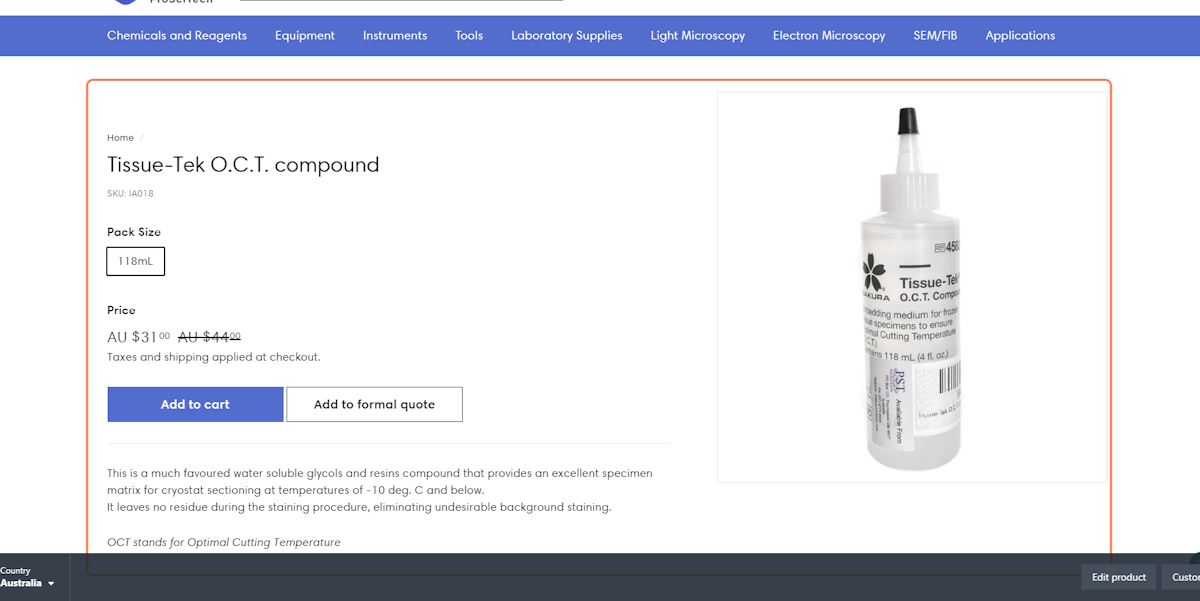

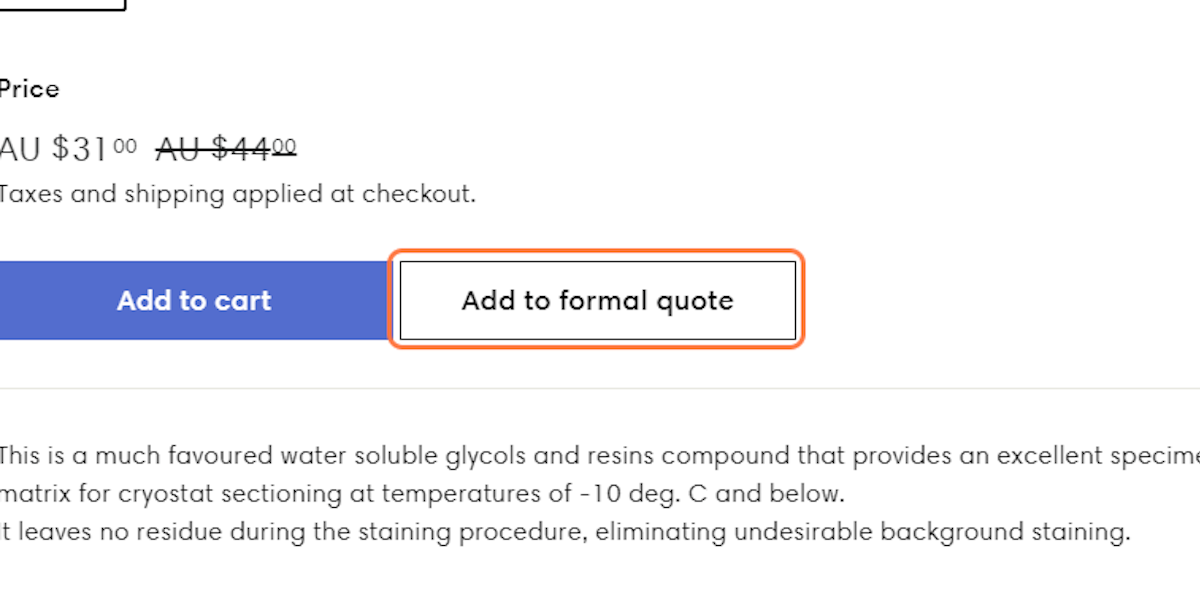

Taxes and shipping applied at checkout.

Electrically/Thermally Conductive (ETC) epoxy adhesives provide solutions to a variety of electrical, electronic, and thermal design problems throughout the laboratories and industries.

ETC Bond 525: Electrically conductive, silver filled, one-part epoxy paste. Good chemical resistance and mechanical strength to 171°C.

ETC Bond 556: Electrically conductive. Silver filled, 1:1 Epoxy paste. Good corrosion resistance and mechanical strength to 171°C

ETC Bond 597A: Electrically and thermally conductive. Silver filled. One part system. Inorganic system for bonding applications up to 649°C.

ETC Bond 598FS: Electrically and thermally conductive. Nickel filled. One part system. Low viscosity. For applications up to 538°C

ETC Bond 568: Thermally conductive. Aluminium filled, 1:1 epoxy paste. Excellent mechanical strength to 204°C

ETC Bond 805: Thermally conductive. Aluminium filled. Two part epoxy paste. Low shrink rate. Excellent mechanical strength to 299°C

ETC Bond 860: Thermally conductive. Aluminium nitride filled. 1:1 epoxy paste. Excellent mechanical & thermal properties to 204°C

Application Notes:

Surface Preparation: All surfaces must be free of oil, dirt, corrosives, oxides, paint or other foreign matter.

Mixing: Two-component products should be mixed thoroughly to a uniform consistency. Preheat high viscosity epoxies to approximately 52°C to facilitate pouring and mixing.

Application: In most cases, the adhesive should be applied to both surfaces maintaining a glue line of less than 25.4µm. After assembling the parts, pressure should be applied to the assembly to prevent warpage and reduce air entrapment. Refer to curing guidelines in above property chart.

Properties:

| Product Number | 525 | 556 | 597A | 598FS |

| Filler | Silver | Silver | Silver | Nickel |

| Mix Ratio by Weight: Resin : Hardener | NA | 1:1 | NA | NA |

| Mixes Specific Gravity, g/cc @ 25°C | 1.85 | 2.8 | 2.3/2.1 | 2.87/1.5 |

| Mixes Viscosity, @ 25°C, cps | Paste | Paste | Paste/Paste | Paste/480 |

| Pot Life, 100g mass @ 25°C, hrs. | N/A | 1 | N/A | N/A |

| Recommended Cure, hr/°F | 2/300 | 24/RT | 2/RT+2/200 | 2RT+2/200 |

| Alternative Cure, hr/°F | 6/250 | 4/170 or 2/210 | -- | -- |

| Temperature Resistance | 171°C | 171°C | 649°C | 538°C |

| CTE, in/in/°F x 106 (°C) | 52.2°C | 25.0°C | 17.3°C | 11.7°C |

| Thermal Conductivity, Btu-in/hr-ft2-°F | 62.2 | 65.0 | 63.1 | 17.9 |

| Tensile Shear Strength, psi * | 2,500 | 1,500 | -- | -- |

| Volume Resistivity, ohm-cm | 0.01 | 0.0052 | 0.0002 | 0.005 |

| Dielectric Strength, volts/mil | - | - | - | - |

| Chemical Resistance | Excellent | Excellent | Excellent | Excellent |

| Colour | Silver | Silver | Silver | Dark Gray |

Properties:

| Product Number | 568 | 805 | 860 |

| Filler | Aluminium |

Aluminium | Aluminium Nitride |

| Mix Ratio by Weight: Resin : Hardener | 1:1 | 100:12 | 1:1 |

| Mixes Specific Gravity, g/cc @ 25°C | 0.85 | 1.66 | 1.9 |

| Mixes Viscosity, @ 25°C, cps | Paste | 85,000 | Paste |

| Pot Life, 100g mass @ 25°C, hrs. | 4.0 | ≤1.0 |

4.0 |

| Recommended Cure, hr/°F | 2/200 | 2/100+2/200 |

2/200 |

| Alternative Cure, hr/°F | 24-48/RT | 24-48/RT |

24-48/RT |

| Temperature Resistance | 204°C | 300°C | 400 (204) |

| CTE, in/in/°F x 106 (°C) | 60.0°C | 45.0°C | 18.7 (33.3) |

| Thermal Conductivity, Btu-in/hr-ft2-°F | 9.0 | 12.5 | 8.5 |

| Tensile Shear Strength, psi * | 1,400 | 1,200 | 1,375 |

| Volume Resistivity, ohm-cm | 1.0 x 105 | 1.0 x 1014 | 1.0 x 1014 |

| Dielectric Strength, volts/mil | 80 | 50 | 250 |

| Chemical Resistance | Excellent |

Good | Excellent |

| Colour | Grey | Grey | Grey |

For comparative data on conductive adhesives:

Store at room temperature

| ETC Bond 525 |

MSDS |

| ETC Bond 556 |

Part A MSDS Part B MSDS |

| ETC Bond 597A | |

| ETC Bond 598FS |

MSDS |

|

ETC Bond 568 |

Part A MSDS Part B MSDS |

| ETC Bond 805 |

Part A MSDS Part B MSDS |

| ETC Bond 860 |

Part A MSDS Part B MSDS |

Images are illustrative only. Please check product details before ordering.