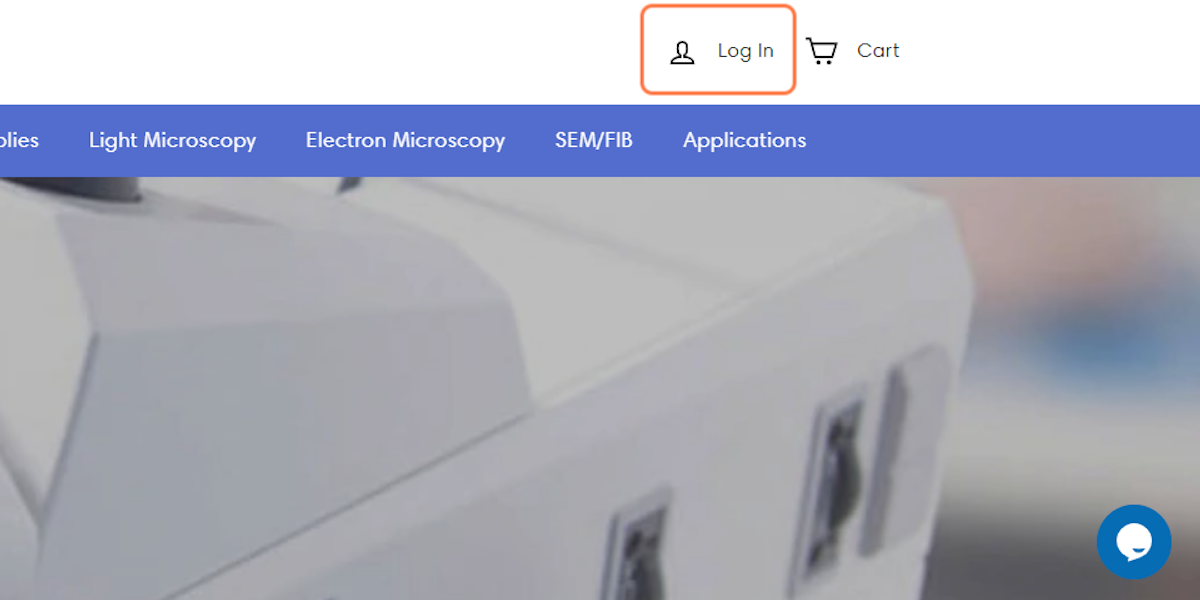

PP3006 CoolLok cryo-SEM transfer system

PP3006 CoolLok cryo-SEM transfer system

The CoolLok offers rapid transfer and cryo temperature observation of specimens for SEM, FIB/ SEM, beam line or other vacuum systems. Applications include thermal protection of beam sensitive specimens and low temperature observation of materials such as plastics, polymers, low-K dielectrics and hard-soft mixtures. The system can also be used for inert gas transfer of ambient temperature specimens from a glove box.

This does not replace the PP3010T, which is a full cryo preparation system (with cold fracturing, sputtering etc.), but can be useful for observing a range of solid, non-water based, materials under cryo conditions.

Walk through the Cryo-SEM Preparation System Laboratory

Features:

- Rapid specimen exchange

- Temperature range down to -190°C

- Off-column cooling with all-day runtime between fills

- Independent cooling of cold stage and cold trap

- Vacuum or inert gas (glove box) transfer

- Rapid specimen freezing option QUO24425

- Cryo workflow options

- Extended warranty option

- Various stubs and shuttles available separately.

System components

Vacuum airlock and cooling gas feedthrough

Mounted onto a suitable vacuum chamber port, the CoolLok consists of a loading chamber body with built-in controls for pumping, venting and transfer. A custom-designed interface flange to the vacuum chamber and connections and fittings to the pumping system are included (see: Pumping below). The interface has cold nitrogen gas feeds to and from the microscope cold stage and cold trap.

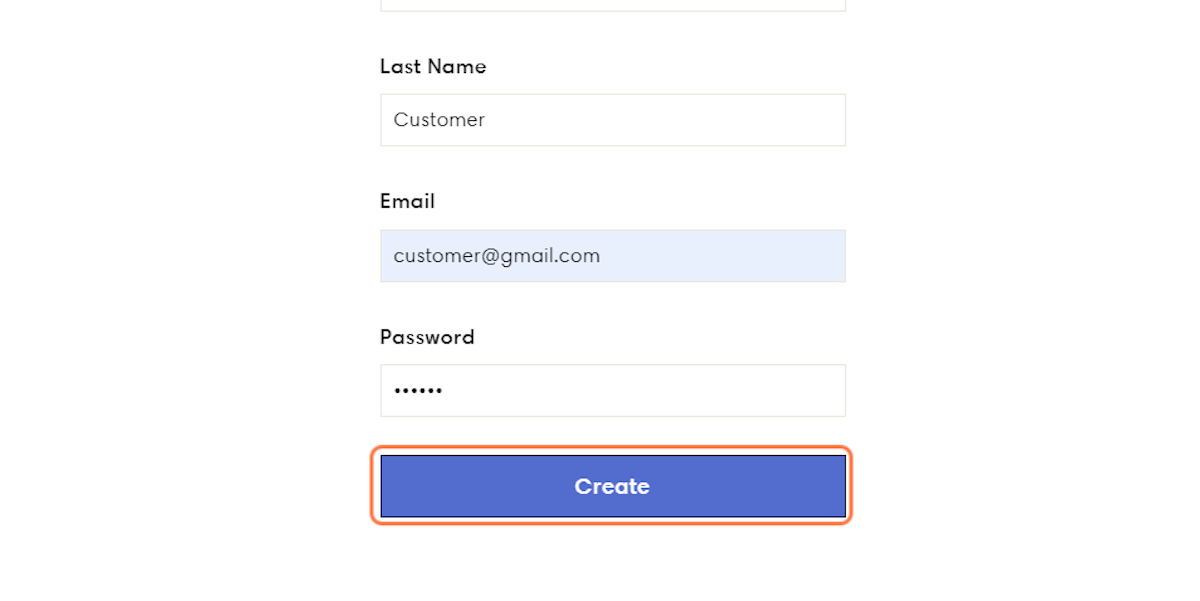

Specimen holders and transfer device

The compact vacuum transfer device has a bayonet fitting to a dovetail-profile specimen holder (shuttle). Standard shuttles are included, but optional holders allow a range specimen types to be handled.

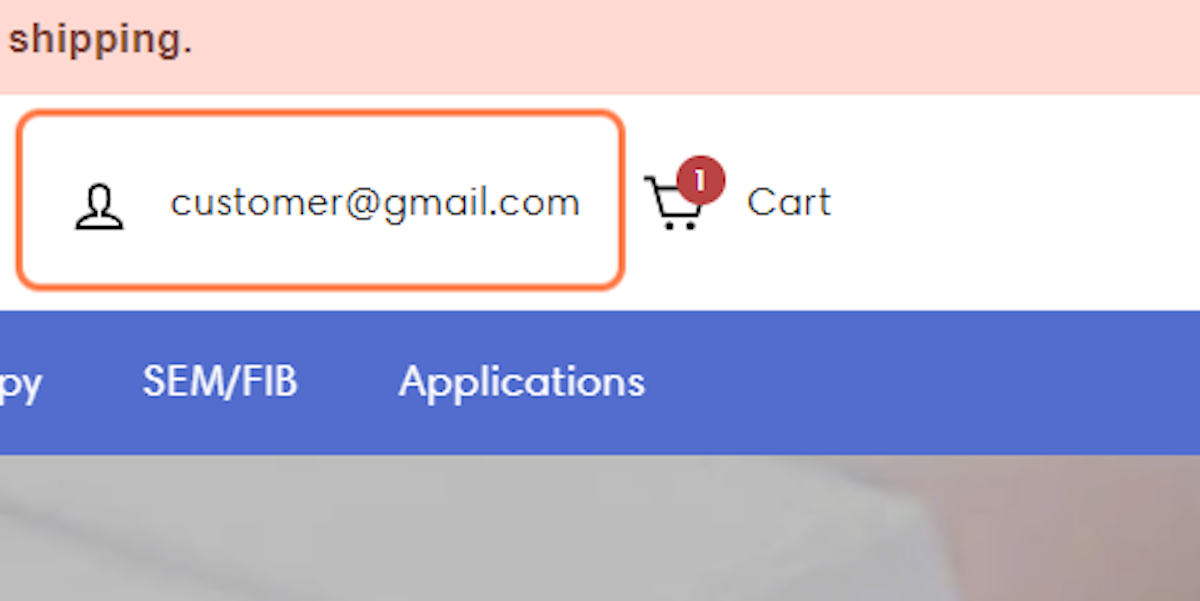

Cold stage and cold trap

A highly stable and thermally isolated nitrogen gas-cooled cold stage attaches to the SEM stage. The location and shape of the cold trap is tailored to suit the internal geometry of the microscope. Both cold stage and cold trap are capable of reaching temperatures down to -190°C with a stability of <0.5°C. For easy specimen exchange an interlocked LED chamber light is fitted.

The cold stage connects to the SEM stage using an adaptor and has a dovetail fitting to accept a cryo specimen holder. When not in use the cold stage is uncoupled and stored within the chamber with the gas and electrical fittings connected.

Cooling dewar, trolley and controller

The cold stage and cold trap are cooled by a floor-mounted, vacuum isolated 21 litre dewar and heat exchanger assembly, which at normal operating temperatures can run for up to 24 hours between fills. The gas lines between the dewar and the SEM interface are vacuum isolated for maximum thermal efficiency.

The cooling dewar is located on a floor-mounted trolley which also houses the temperature monitor/controller for the cold stage and temperature monitor for cold trap, plus nitrogen gas flow controllers.

Rapid freezing station (QUO24429)

With the standard CoolLok, specimen freezing is by contact with the SEM cold stage following transfer and therefore freezing rates are relatively slowly. This is suitable for hard, non-hydrated specimens, but for liquid-based material rapid freezing is essential to reduce the detrimental effects of ice crystal growth and to allow through-vacuum transfer onto the cold stage.

For these applications the optional QUO24429 nitrogen slush freezing station is required. However, for many applications (especially life sciences) cold fracturing and sputter coating are essential process steps and require the advanced capabilities of the QUOPP3010T - a full cryo-SEM preparation system.

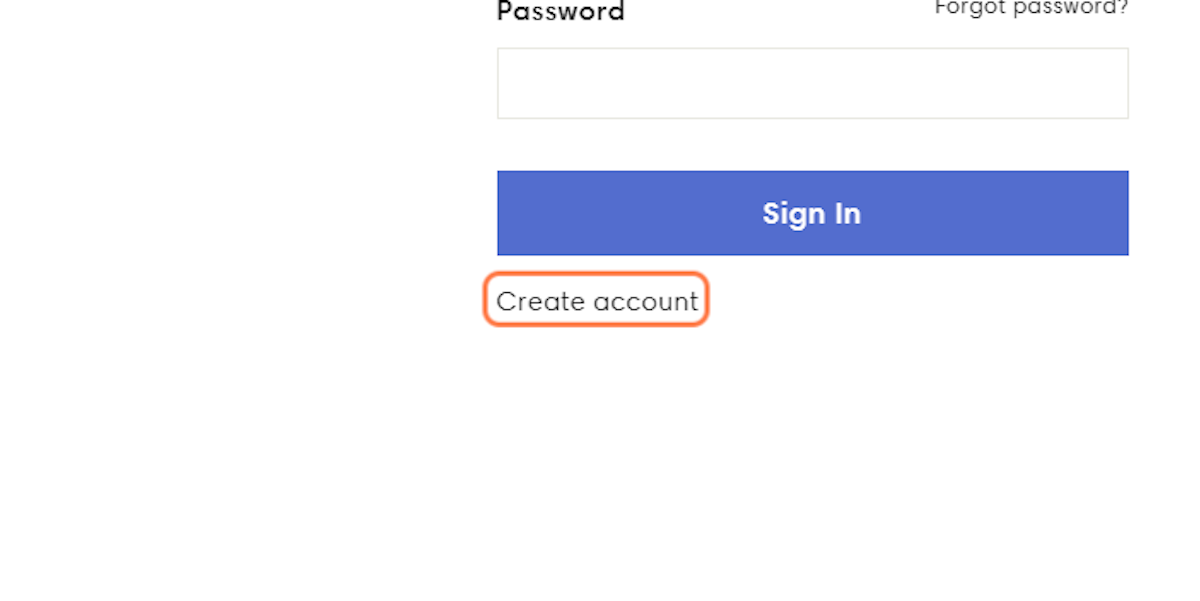

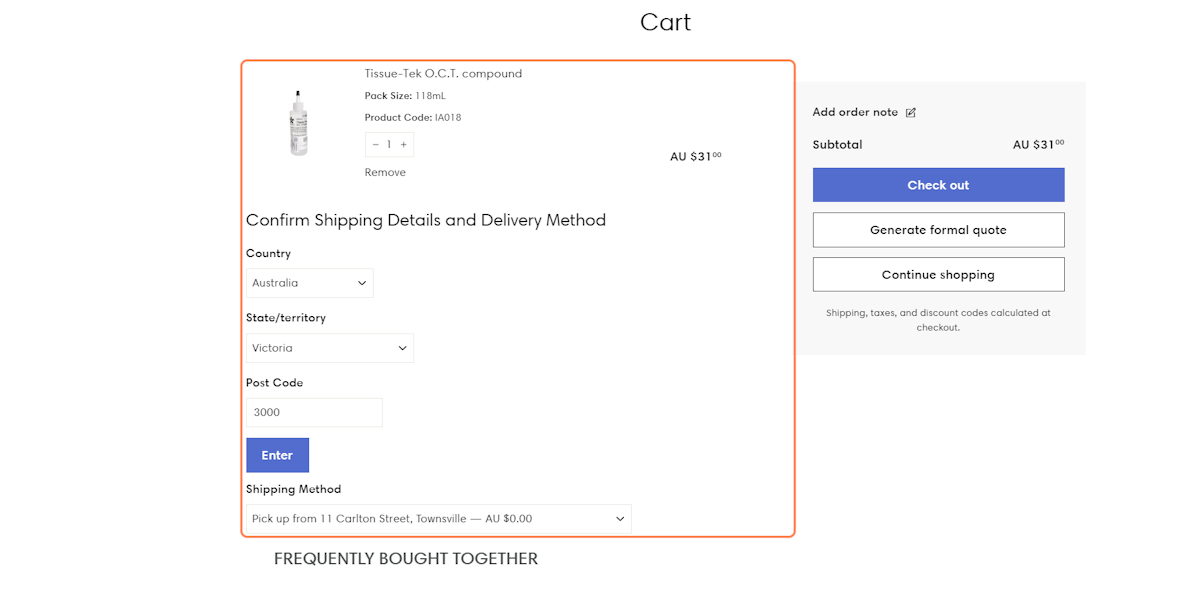

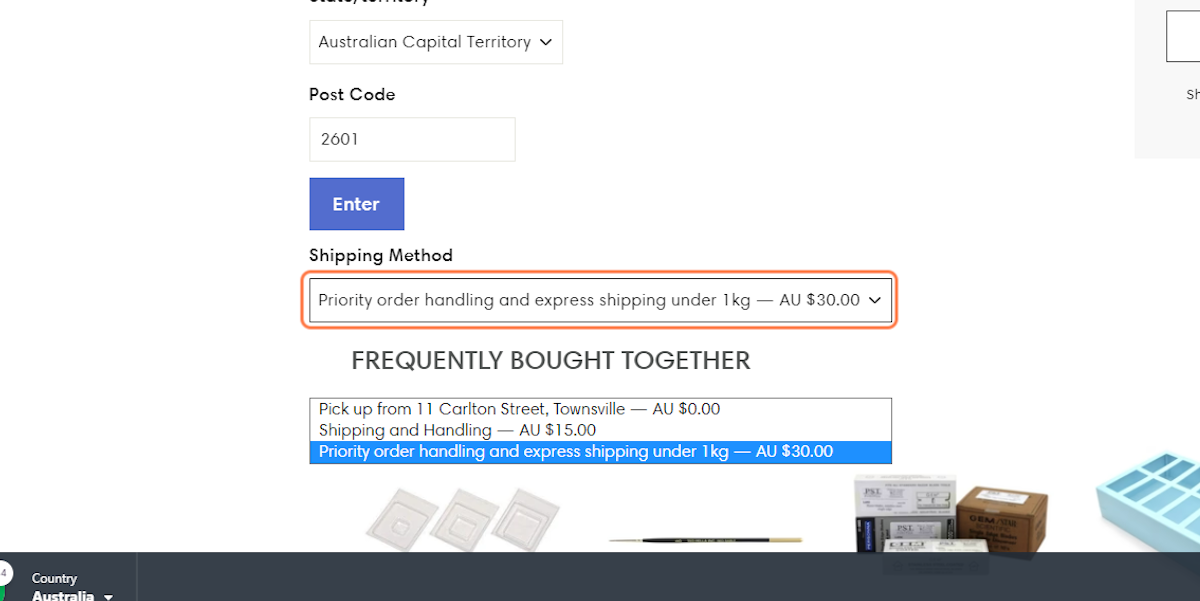

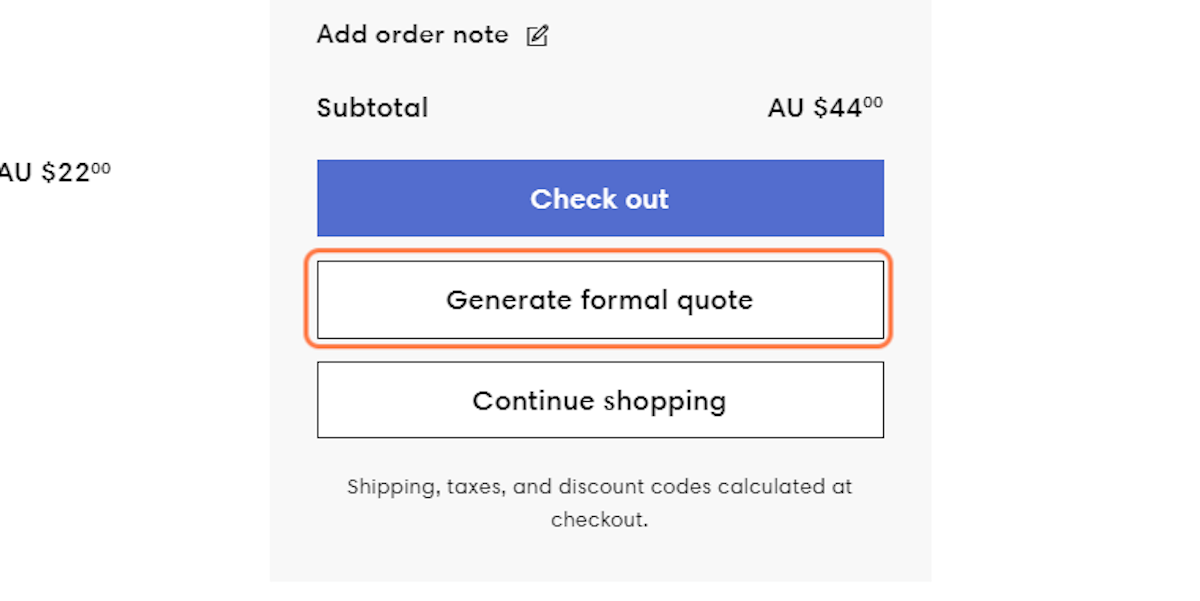

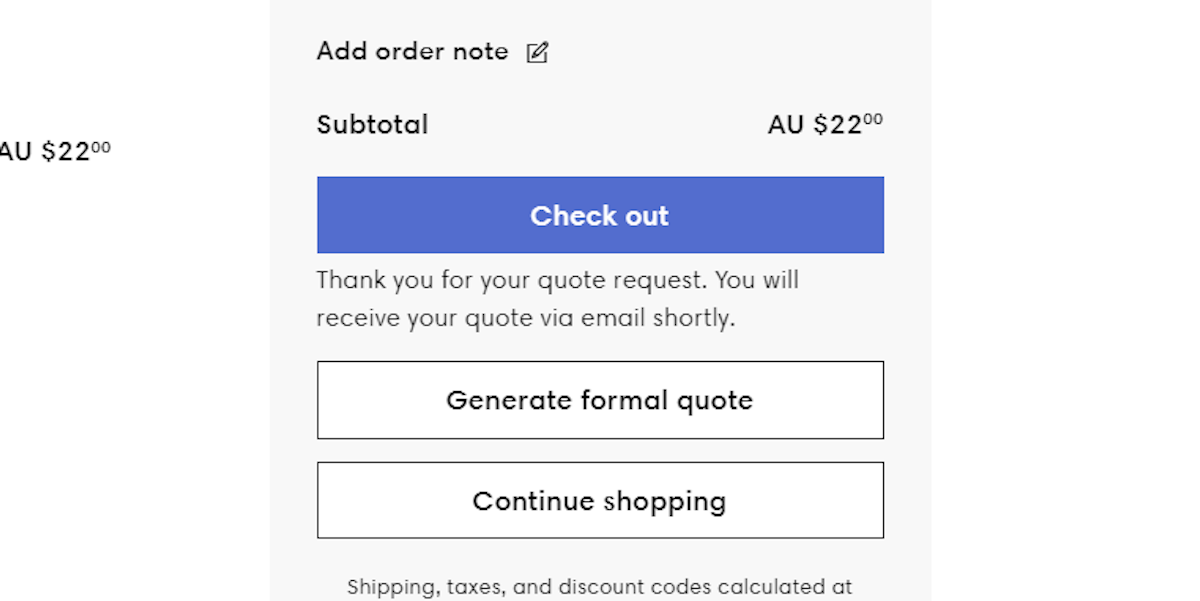

Using the CoolLok

The specimen is mounted on a suitable holder (shuttle) and the transfer device fitted onto the airlock and the dead space evacuated to a set vacuum level. The gate valve is opened and the specimen guided onto the SEM stage.

For transfers from other vacuum systems, or a glove box, additional interface flanges are available on request. Vacuum transfers can be made from the optional QUO24429 trolley-mounted nitrogen slush freezing station, if fitted.

Pumping

The CoolLok requires either a rotary pump or an oil-free turbo pumping station (see Ordering Information).

Specifications:

| Model |

PP3004 | PP3005 | PP3006 |

| Temperature | Ambient | RT to -190°C | |

| Cooling runtime | N/A | Up to 24hrs | |

| Dewar capacity | N/A | 30L | |

| Cool down time to -190°C * | N/A | <15 minutes *Under standard laboratory conditions |

|

| Rapid freezing (slushy LN2) | N/A | Optional (QUO24429) | |

| Dewar trolley footprint | N/A | 50 x 50cm | |

| Airlock weight | 2.5kg | ||

| Pumping requirements | Turbo Pump | Rotary Pump | Turbo Pump |

| Nitrogen gas | Venting and valve operation | Venting and cooling | |

| Power requirements (excluding pump) | 300W | ||

| Maximum specimen size | Flat specimens up to 23 x 26mm. For taller specimens the maximum height will reduce from a mid-point of 9mm. | ||

Ordering Information

| QUOPP3006 |

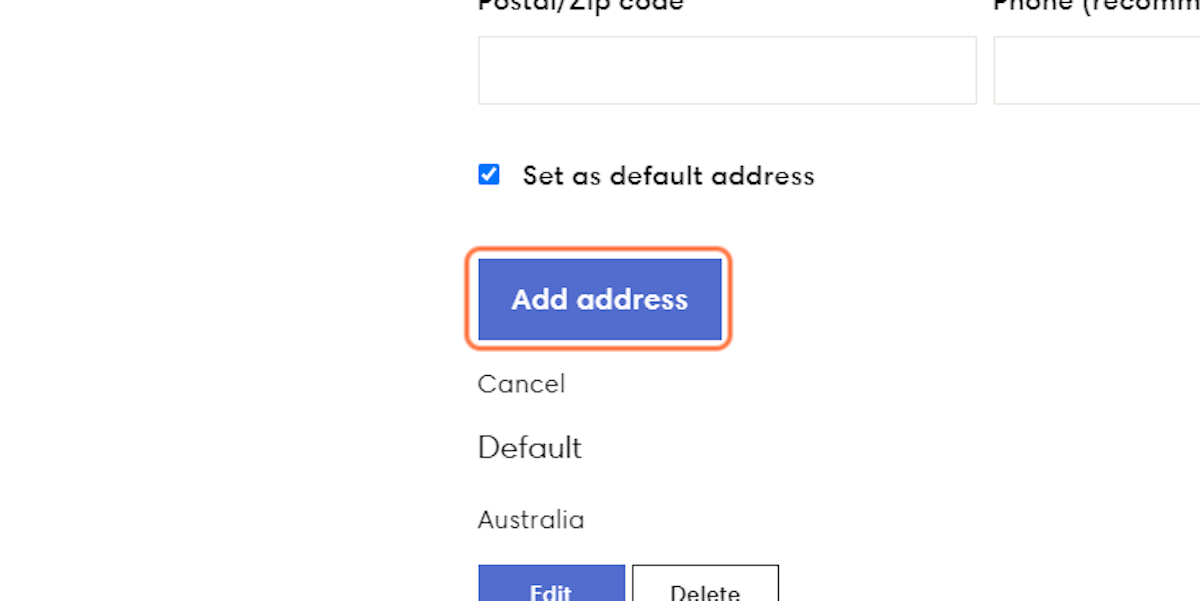

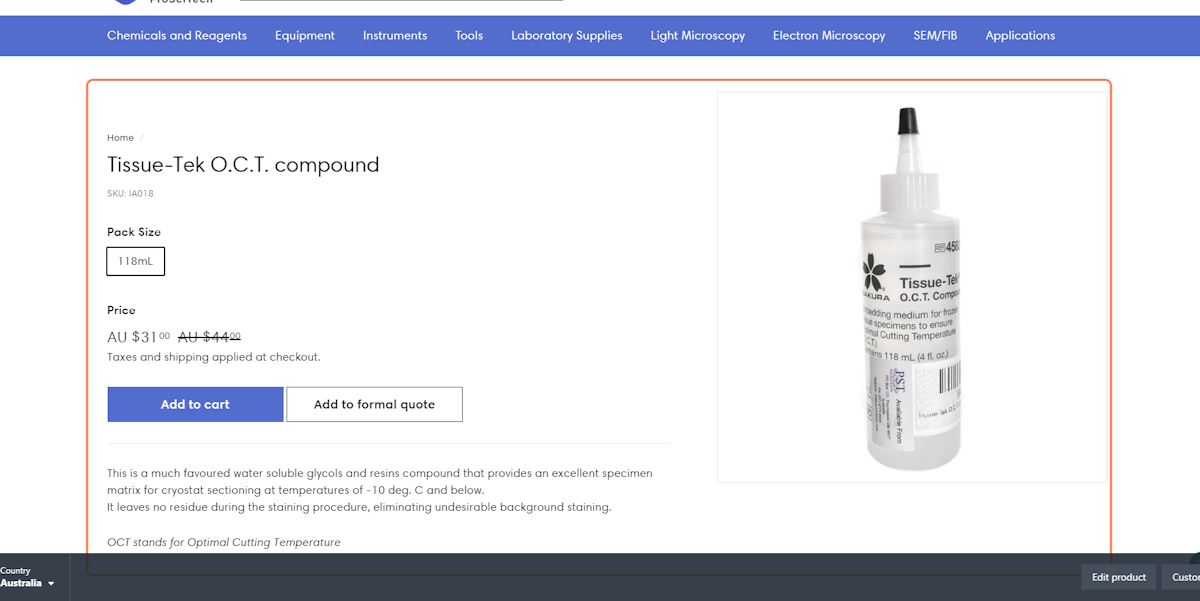

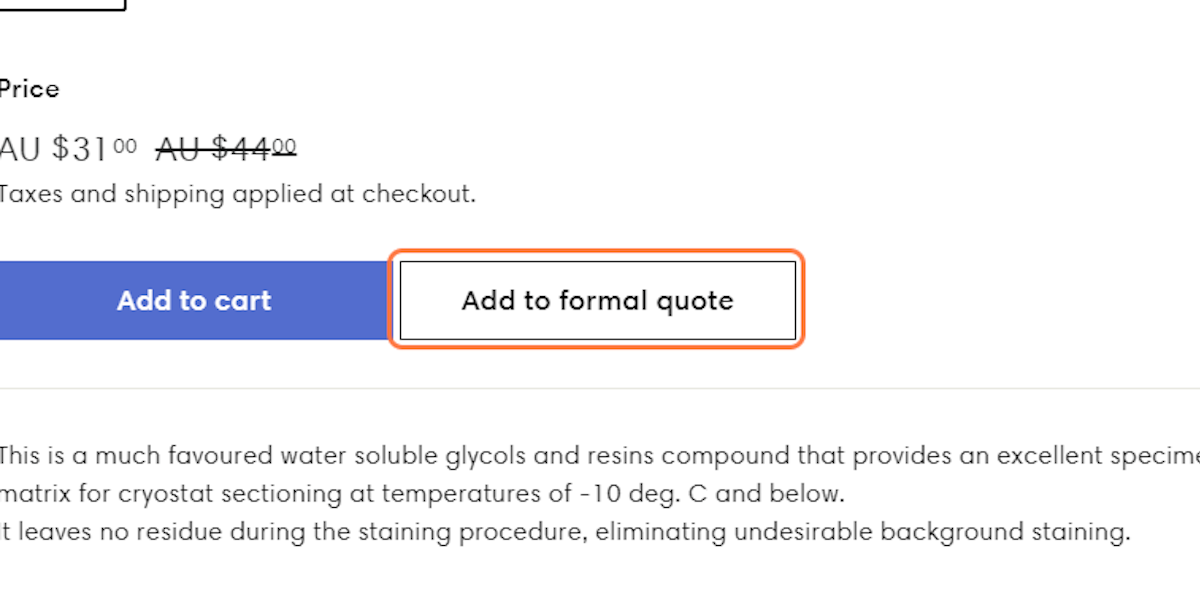

Includes: Airlock assembly. Pump and vent control buttons, gate valve and fittings to the pumping system (see: Pumping below). Custom-designed interface flange to the microscope vacuum chamber. Cooling system. Nitrogen gas cooled stage with heater and sensor and cold trap with temperature sensor. Precise temperature control with a range down to 190°C, 21L liquid nitrogen dewar with trolley, heat exchanger and LED chamber light. QUO12340 specimen transfer device. 3 x QUOAL200077B specimen shuttle (for 10mm cryo stubs) QUO12434 blank specimen shuttle QUO20720 specimen shuttle with holding clips QUOE7402 blank 10mm stubs, pack/10 5 x QUOE7449 multi-purpose specimen stubs. Note: other optional holders are available. Specimen mounting compounds (colloidal graphite and Tissue-Tek), interlock cable and pump fittings. |

| Pumping - The PP3006 CoolLok requires either a rotary pump or an oil-free, high vacuum turbomolecular pumping station (recommended). | |

| QUO13034 | Pfeiffer DUO 6 two-stage rotary vacuum pump, 240V |

| Options and accessories: | |

| QUO24429 | Rapid cooling station consisting of a floor-mounted trolley, liquid nitrogen freezing chamber mounted into the work surface which interfaces to the cryo transfer device, connections to vacuum pump (order separately). |

| QUOPP7450/60L | Pressurised (60L) liquid nitrogen dewar. Boil-off nitrogen gas is used for cooling stage and cold trap. |

| QUO13296 | Sircal in-line gas dryer. Helps to reduce the water content of the nitrogen gas supply, if an external gas source is used. |