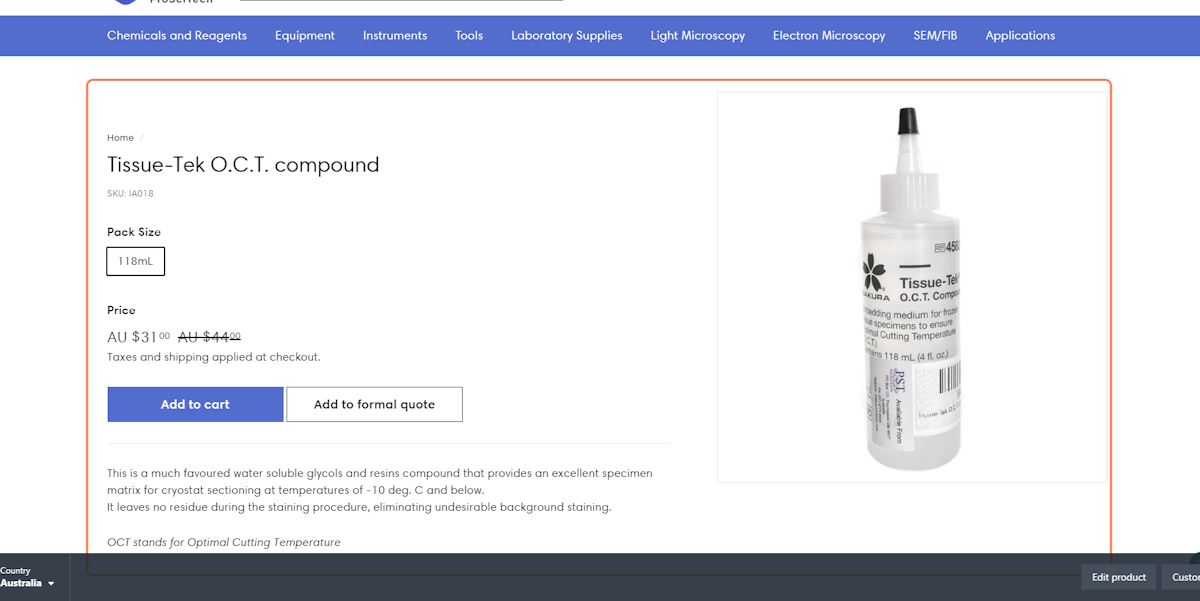

PELCO Dimpler precision specimen thinning for TEM

PELCO Dimpler precision specimen thinning for TEM

The PELCO Dimpler is the latest model in the evolution of the Dimpler line formerly available from South Bay Technology and provides Automated Precision Thinning of Specimens for TEM Analysis. It is a precision electro-mechanical metallographic lapping instrument that will continuously monitor and control dimpling parameters and accurately terminate at a preset specimen thickness. This breakthrough in electronic and mechanical integration has added repeatability and reliability to the dimpling process, as well as automation.

Tools

The standard dimpling tools include flatting and dimpling tools, in both unpadded versions for faster material removal and padded versions for polishing. Tools are made from 316 Stainless steel. Flatting tools such as Tools 1i and 2i, and the Large Area Tools have a flat profile while Dimpling Tools such as 3i and 4i have a radius profile to produce a pronounced dimple. The flatting tools will still produce a dimple with the lowest point at the centre of rotation, but it will have a much shallower height differential across the dimple.

A variety of padded and unpadded tools are available to meet many dimple polishing process requirements and other accessories are available:

- PELCO Dimpler platen sets

- PELCO Dimpler tools

- PELCO Dimpler tool repadding accessories

- PELCO Dimpler large sample kit

- PELCO abrasive slurry dispenser

- PELCO Dimpler slurry mat

The PELCO Video Alignment Microscope is also an essential accessory for the PELCO Dimpler, particularly for deprocessing/delayering and site-specific polishing applications.

Specifications:

| Z Offset | Accuracy: 1 micron |

|---|---|

| Range: 2000 microns | |

| Z Termination Accuracy | Tools 1i / 3i: <±1 micron |

| Tools 2i / 4i: <±2 microns | |

| Tool Force | Range: 1 - 200g |

| 1g steps |

|

| Balance | Sensitivity: 1g |

| Range: 50g | |

| Tool Speed | 100 - 600 RPM |

| Specimen Platen Speed | 10 RPM |

| Tool Shaft | 0.5micron TIR |

| Tools 1i / 3i: <±1 micron TIR | |

| Tools 2i / 4i: <±2 microns TIR | |

| Platen Surface | < 0.5 micron TIR |

| Dimensions | 68.6cm L x 35.6cm W x 33cm H |

| Weight | 32kg |

| Electrical | 100-240VAC, 50/60Hz |

Several operating functions of the PELCO Dimpler are built in to facilitate repeatable, usable dimpled samples:

Z Position - The display indicates the termination set point and the dimple depth from the Non-Contact Sensor is analog to digital.

Termination - The Non-Contact Position Sensor measures the location of the fulcrum arm which corresponds precisely to the thickness of the specimen. This sensor has an accuracy of better than one micron.

Damping of the arm is accomplished by using position information from the Non-Contact Position Sensor, processing it and feeding it back to the arm motor, which controls the up/down force of the arm. The position sensor and the processing circuit is fast enough to actively dampen any vibration the arm may experience.

Automated Controls make the dimpling process more repeatable and easy to use. Tools are raised and lowered at the touch of a button; dimpling force, damping force, fine balance, and Z offset (termination point) all are set from the front panel.

Specimen Mounting on optically smooth sapphire flats. Low thermal mass of the flat reduces mounting and dismounting times and the smooth surface allows the dimpled specimens to be gently slipped off.

Working Interface - A user can control the dimple depth and removal with a virtually seamless padded tool. This position control allows the dimpling force to approach zero within 1g increments.

Images are illustrative only. Please check product details before ordering.