PELCO tripod polisher for precision sample thinning

PELCO tripod polisher for precision sample thinning

The PELCO Tripod Polisher 590 was designed by researchers at the IBM East Fishkill Laboratory* to accurately prepare TEM and SEM samples of pre-specified, micron-sized regions. For TEM samples, this technique has been used successfully to limit ion milling times to less than 15 minutes and, in some cases, has eliminated the need for ion milling. Although this technique was designed for preparing semiconductor cross-sections, it has been used to prepare both plan-view and cross-section samples from such diverse materials as ceramics, composites, metals, and geological samples.

Features:

- Precise cross-sectioning at the TEM level

- Repeatable and rapid production of TEM samples

- Reduces ion milling time to minutes as opposed to hours

- Produces large thin areas over the entire specimen

Operation - Standard Technique

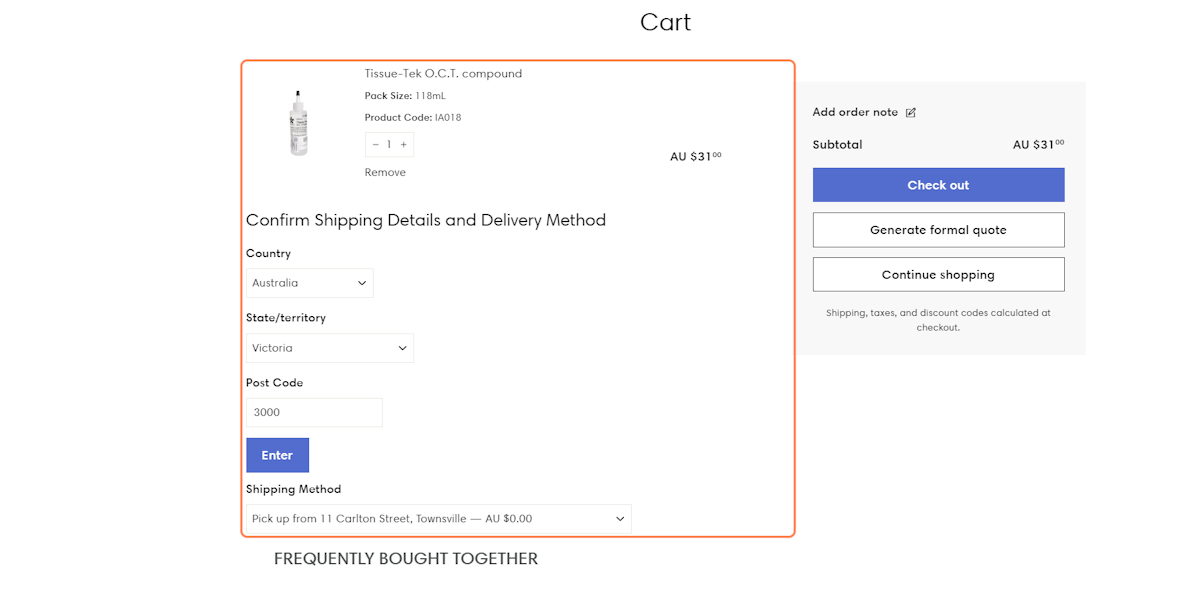

The PELCO Tripod Polisher 590 can be used to prepare a sample for both SEM and TEM cross-sectional analysis. To accomplish this, the sample is mounted on the face of a special SEM stud which is clamped into the slotted L-bracket of the PELCO Tripod Polisher 590. Initial grinding is done on a 15µm metal bonded diamond disc. Further lapping and polishing continues with a succession of diamond films ranging in size from 30µm to 0.5µm. The final polish is done with a colloidal silica suspension. As lapping progresses, the two rear micrometers are used to adjust the plane of polish. With periodic examinations in an inverted microscope, the plane of polish is adjusted until it is parallel to the plane of interest. At this point the SEM stud may be moved to an ion mill for a quick milling to remove fine scratches, polishing debris and to give the surface topography prior to SEM analysis. The SEM stud can be mounted directly in the SEM for analysis. When analysis is complete, a TEM sample of the same area is made. The sample is removed from the SEM stud and attached to a single aperture TEM grid. The slotted L-bracket is removed and the TEM grid is attached to the round sample mount which is affixed to the center of the polisher. The sample is now mechanically thinned using Diamond Lapping Film. During this process the sample is periodically examined in an inverted microscope and the micrometers are adjusted to maintain the correct plane of polish. The sample is FINAL polished to 1µm or less and then ion milled for up to 15 minutes.

Operation - Wedge Technique

The preferential thinning and surface topography that occurs in briefly ion milled samples makes the study of interfaces between dissimilar materials difficult. These problems can be reduced by completely eliminating the ion milling step and mechanically polishing the sample to electron transparency by employing the wedge technique. With this technique the SEM stud is replaced, in the slotted L-bracket, with a Pyrex insert. The sample is mounted on the face of this insert. After the plane of interest is obtained, the sample is removed and mounted on the bottom of the Pyrex insert. The two rear micrometers are adjusted and the micrometer nearest the sample is retracted to produce a wedge shape as material is removed from the sample. The sample, with the features of interest at the apex of the wedge, is thinned from the back side until the edge of interest is ~1µm thick. The sample is then polished on a final polishing cloth with a colloidal silica suspension until thickness fringes are visible (below a few thousand angstroms). The sample is then removed from the Pyrex insert and attached to a single aperture TEM grid for analysis.

Included Accessories per Kit

| Accessories | PELCO Tripod Polisher 590TEM |

PELCO Tripod Polisher 590SEM |

PELCO Tripod Polisher 590TS |

| Wedge Polishing Mount | 1 | - | 1 |

| Slotted L-bracket with Easy Locking Lever | 1 | 1 | 1 |

| Pyrex Wedge Polishing Stub | 1 | - | 1 |

| Pyrex Insert Large | 1 | - | 1 |

| Heater Block | 1 | - | 1 |

| SEM Stub | - | 4 | 4 |

| Glass Leveling Slide | 2 | 2 | 2 |

| Microscope Stand | 1 | 1 | 1 |

| Delrin Foot for Micrometer | 3 | 2 | 3 |

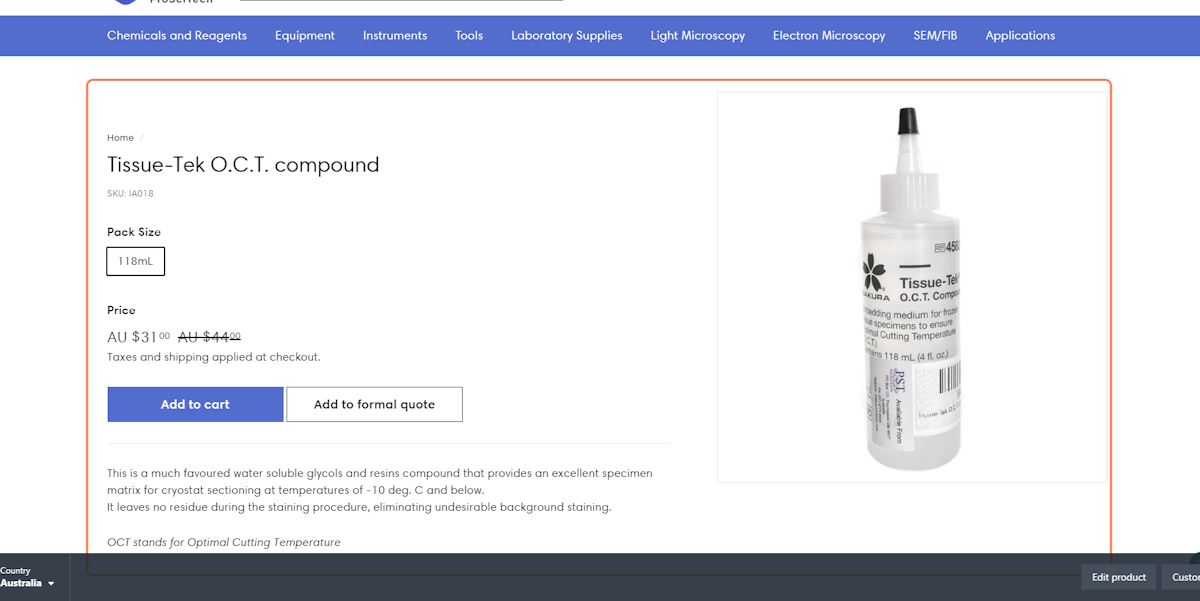

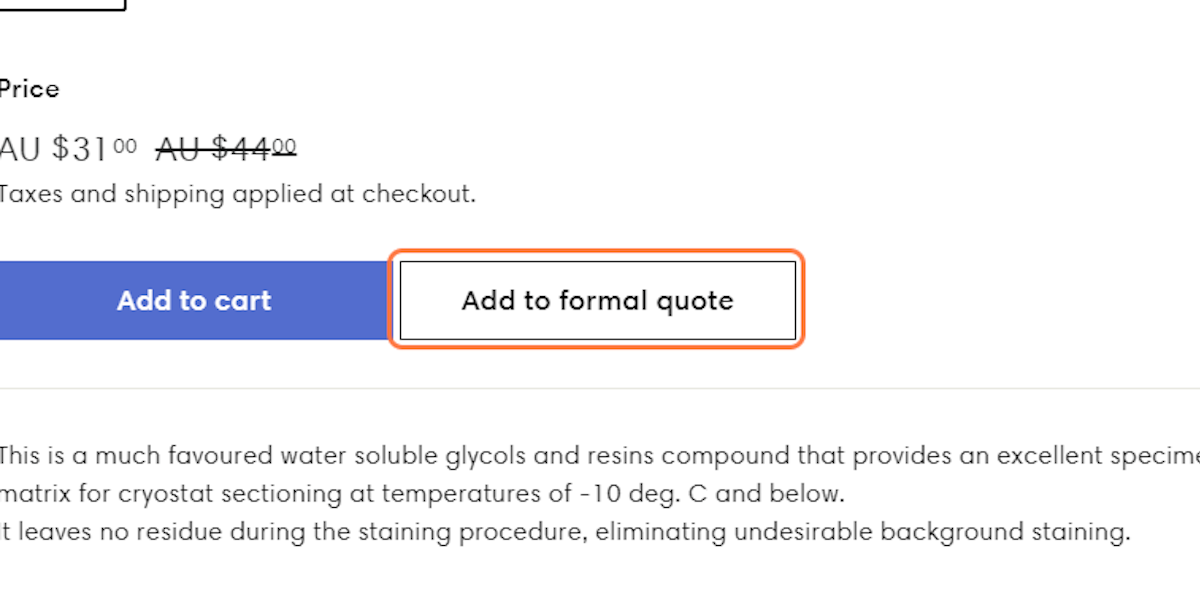

Images are illustrative only. Please check product details before ordering.